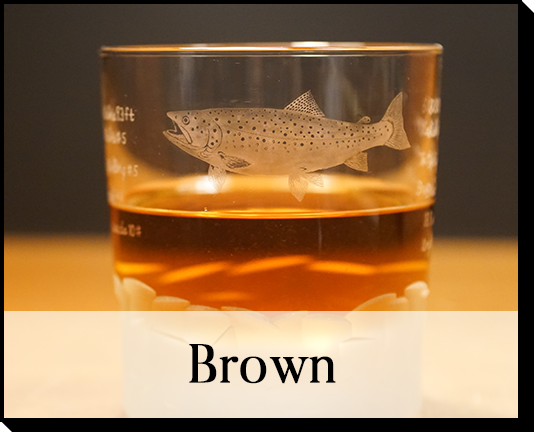

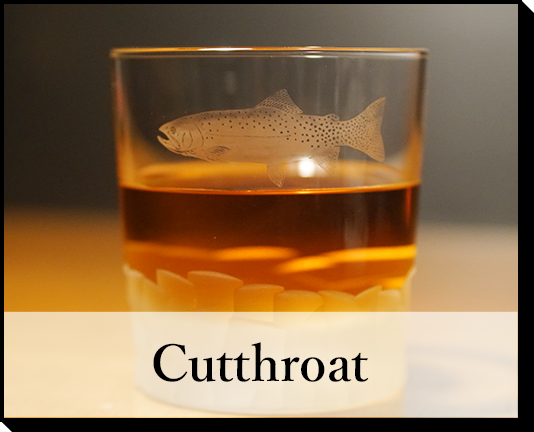

About glass etching technique

The three major glass etching techniques are sandblasting, drill etching, and chemical etching.

In the sandblasting method, an air compressor blows sand at high speed to make the surface of the glass matte. This is the most common technique, but it does not allow for detailed depictions such as fine lines or for expressing gradations.

Drill etching is a technique for drawing letters and patterns with a fine drill, such as that used by dentists, but it is not always suitable for surface expression.

Most importantly, it is not suitable for processing glass tableware due to the grooves on the glass surface that reduce its strength.

Chemical etching uses a fluorine solution to create an image on glass.

It doesn’t require any facility or tools like other techniques, so it’s easy to get started.

By changing the concentration of the chemical solution and adjusting the melting rate, we succeeded in creating an accurate gradation.

- Company Name

- LLC Golden Pond

- Capital

- $10,000-

- Business content

- Etching tumbler making and export.

- Representative employee

- Nobuhiko Hagino

- Postal Code

- 818-0034

- Address

- 2-5-5 Utukusigaoka minami Chikusino City Fukuoka,Japan

- Business Time

- 9:00~18:00

- Regular holiday

- weekend・holidays

- Expenses other than the price

- Packing cost・Fare

- How to order

- e-mail order

- Method of payment

- Wise (TransferWise)・Bank transfer(Japan domestic only )

- Payment deadline

- Within a week from designated date.

- Returns

- Because it is made to order, it is not possible after ordering.

- Exchange

- Only possible when the product is damaged due to a transportation accident.